Our Mexico 2 foot by 3 foot Polyester Flag is made of light-weight polyester for durabilty and is dye-sublimated to produce vivid bright colors.

This is a small flag, and is the can fly on most standard house poles or smaller flag poles.

We have reinforced our Mexico 2 foot by 3 foot Polyester Flag on the header (hoist) side with header tape and on the fly side with a hem with 4 rows of stitching.

The dye-sublimation or dye-infusion process is applied to one side of the fabric and infused through the fabric, the result is that both sides of the fabric have vibrant colors, with the back side having the reverse print. This is standard for flags.

We offer quantity discounts on this product.

UPC: 841098117146 SKU: 23P-MEX

Original Retail: $7.99 Phone Price: $7.99 Web SALE price as listed.

Quantity Discounts are applied at checkout.

Data sheet

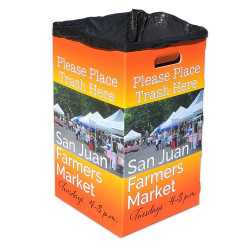

In sublimation printing, unique sublimation dyes are transferred to sheets of “transfer” paper via liquid gel ink through a piezoelectric print head. The ink is deposited on these high-release inkjet papers, which are used for the next step of the sublimation printing process. After the digital design is printed onto sublimation transfer sheets, it is placed on a heat press along with the substrate to be sublimated.

In order to transfer the image from the paper to the substrate, it requires a heat press process that is a combination of time, temperature and pressure. The heat press applies this special combination, which can change depending on the substrate, to “transfer” the sublimation dyes at the molecular level into the substrate. The most common dyes used for sublimation activate at 350 degrees Fahrenheit. However, a range of 380 to 420 degrees Fahrenheit is normally recommended for optimal color.

The end result of the sublimation process is a nearly permanent, high resolution, full color print. Because the dyes are infused into the substrate at the molecular level, rather than applied at a topical level (such as with screen printing and direct to garment printing), the prints will not crack, fade or peel from the substrate under normal conditions.

From Wikipedia